Image Source: rmpusa.com

How Many Turf Pellets On A Football Field?

A typical American football field uses between 1.5 to 2.5 million pounds of infill, primarily made of rubber or sand pellets, to simulate the feel and performance of natural grass. The exact number of individual pellets varies greatly depending on the specific infill material, its density, and the total area of the field, making a precise count impractical. This infill is crucial for the functionality and longevity of the entire sports turf system.

The Foundation of Modern Sports: Artificial Turf Pellets

Artificial turf has revolutionized sports played on grass, offering consistent playability, reduced maintenance, and year-round usability. At the heart of this innovation lies the infill system, a critical component that supports the artificial turf blades and provides shock absorption. These infill materials, often referred to as turf pellets, play a vital role in the performance and safety of the playing surface. Whether it’s for football, soccer, or other sports, the quantity and type of infill are carefully considered during turf installation to achieve the desired playing characteristics.

Deciphering the Infill: More Than Just “Grass”

When people see artificial turf, they often focus on the synthetic grass blades. However, the granular material nestled between these blades, the infill, is equally important. This infill has several key functions:

- Blade Support: It holds the artificial turf blades upright, preventing them from flattening. This is crucial for maintaining the aesthetic and the performance of the field. The density of the artificial turf blades and how they are tufted into the backing significantly influences how much infill is needed and how effectively it supports them.

- Shock Absorption: The pellets cushion players, reducing the impact on joints and muscles during tackles, jumps, and sprints. This is a primary safety feature, especially in high-impact sports like football.

- Drainage: Infill materials help wick away moisture, allowing water to pass through the turf system efficiently.

- Ball Roll: The type and depth of infill affect how a ball rolls and bounces on the surface, mimicking the behavior of natural grass.

Types of Turf Pellets: A Material World

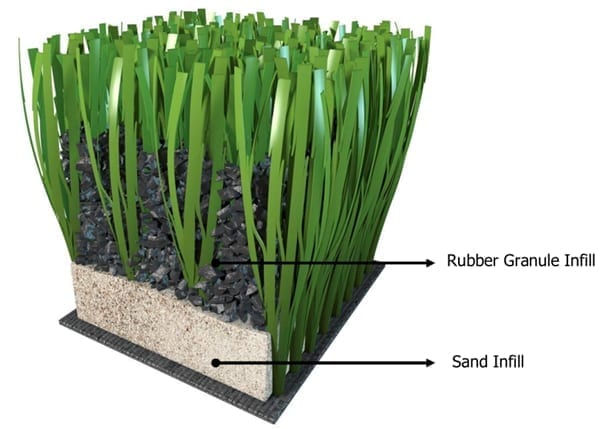

The world of turf infill is diverse, with different materials offering unique properties and playing characteristics. The most common types of turf pellets include:

- Crumb Rubber: Derived from recycled tires, crumb rubber is the most prevalent infill material, especially for football fields. It provides excellent shock absorption and a familiar feel.

- Characteristics: Dark black, granular, good elasticity.

- Advantages: Cost-effective, excellent shock absorption, readily available from recycling programs.

- Disadvantages: Can retain heat, potential for odor, some concerns about microplastic shedding.

- Sand: Often used as a base infill or in combination with other materials, sand provides stability and drainage.

- Characteristics: Fine granular material, typically silica or washed sand.

- Advantages: Neutral color, good for drainage, provides density and stability.

- Disadvantages: Less shock absorption than rubber, can harden over time, may become abrasive if not maintained.

- Performance Infills: These are specialized infill systems designed to improve specific playing characteristics, such as cooling, ball roll, or player safety. They can include coated sand, cryogenic rubber, or proprietary blends.

- Characteristics: Varies widely based on the specific product.

- Advantages: Enhanced cooling properties, improved moisture management, superior player comfort.

- Disadvantages: Typically higher cost than standard crumb rubber or sand.

The choice of turf types also influences the infill requirements. Different artificial grass blades have varying lengths, densities, and backing structures, all of which affect how much infill is needed and how it performs.

Quantifying the Pellets: A Field Coverage Perspective

Estimating the sheer number of individual pellets on a football field is a complex calculation. It’s more practical to consider the volume and weight of infill required for adequate field coverage.

Standard Football Field Dimensions:

A regulation American football field, including end zones, is approximately 360 feet long and 160 feet wide.

Total Area = 360 ft * 160 ft = 57,600 square feet.

Infill Depth:

The recommended infill depth for artificial turf on a football field typically ranges from 1.5 to 2.5 inches. This depth is crucial for achieving the desired shock absorption and player safety.

Calculating Volume:

Let’s assume an average infill depth of 2 inches (0.167 feet) for a field of 57,600 square feet.

Total Infill Volume = Area × Depth

Total Infill Volume = 57,600 sq ft × 0.167 ft

Total Infill Volume ≈ 9,619 cubic feet

Converting to Weight:

The weight of the infill depends heavily on the material’s density.

- Crumb Rubber: The density of crumb rubber varies, but it’s roughly around 40-50 pounds per cubic foot.

- Sand: The density of dry sand is typically around 100-110 pounds per cubic foot.

Example Calculation (Crumb Rubber):

Using an average density of 45 lbs/cubic foot:

Total Weight = Volume × Density

Total Weight = 9,619 cubic feet × 45 lbs/cubic foot

Total Weight ≈ 432,855 pounds

Example Calculation (Sand):

Using an average density of 105 lbs/cubic foot:

Total Weight = Volume × Density

Total Weight = 9,619 cubic feet × 105 lbs/cubic foot

Total Weight ≈ 1,010,000 pounds

These calculations illustrate why the initial estimate of 1.5 to 2.5 million pounds is often cited, as it encompasses a broader range of infill depths and densities, as well as potentially including a layer of sand beneath the rubber infill for added stability. The actual quantity can fluctuate based on specific product specifications and installation practices.

The Intricacies of Turf Installation: A Precise Process

Turf installation is a detailed process where the correct amount of infill is crucial. During installation, the artificial turf system is laid out, and then the infill is spread evenly across the surface. This is typically done using specialized blowers or spreaders that ensure consistent field coverage.

Key Steps in Infill Application:

- Even Spreading: The infill material is applied uniformly across the entire playing surface.

- Brushing/Grooming: After spreading, the infill is brushed into the base of the artificial turf blades. This helps to stand the blades up, provide stability, and ensure even distribution. This process is critical for the overall performance of the sports turf system.

- Compaction (if applicable): For certain infill types, light compaction might be necessary to settle the material.

The success of the turf installation relies heavily on achieving the correct infill density and depth. Too little infill can lead to poor shock absorption and premature wear of the turf blades, while too much can make the field too firm or affect ball roll.

Football Field Maintenance: Keeping the Pellets in Play

Proper football field maintenance is essential to ensure the longevity and optimal performance of the artificial turf system. The infill plays a significant role in this ongoing care.

Regular Maintenance Tasks:

- Brushing and Grooming: Periodically brushing the infill helps to keep the artificial turf blades upright and prevent compaction. This also helps to remove debris and aerate the infill layer.

- Infill Top-Up: Over time, infill can migrate or be displaced, especially with heavy use. Top-ups of infill are periodically required to maintain the correct depth and density.

- Debris Removal: Leaves, dirt, and other debris can accumulate on the surface and in the infill. Regular cleaning is necessary to maintain the integrity of the system and prevent issues like mold growth or poor drainage.

- Weed Control: While artificial turf is designed to prevent weed growth, in some cases, weeds can emerge from the edges or through the backing. Addressing these promptly is important.

For soccer field turf, the maintenance principles are similar, emphasizing consistent infill levels and surface cleanliness to ensure good ball-to-surface interaction and player safety.

The Science Behind the Blades: Turf Density and Blade Spacing

The number of artificial turf blades per square inch, known as turf density, is a critical factor in the overall appearance and performance of the field. Higher turf density generally means a lusher, more robust surface.

- Turf Density: Measured in stitches per unit area, it dictates how closely packed the artificial turf blades are.

- Blade Spacing: The distance between individual tufts of artificial grass.

These factors directly influence how much infill is needed. A field with higher turf density and narrower blade spacing will require more infill to support and protect the greater number of blades. The construction of the artificial grass blades themselves – their height, shape, and material – also impacts how they interact with the infill and the overall playing experience.

Frequently Asked Questions (FAQ)

Q1: How often does artificial turf need infill top-ups?

A1: The frequency of infill top-ups depends on usage intensity, climate, and the quality of the initial installation. Typically, fields may require top-ups every 1-3 years.

Q2: Can I use household sand for my artificial turf?

A2: It is not recommended to use just any household sand. Washed, kiln-dried silica sand or specialized infill sand is typically recommended. Avoid play sand or builder’s sand, as these can contain impurities or be too fine, leading to compaction and drainage issues.

Q3: Does the type of infill affect how hot the field gets?

A3: Yes, infill type significantly impacts surface temperature. Crumb rubber, especially dark-colored rubber, tends to absorb and retain more heat than sand or specialized cooling infills.

Q4: What happens if there isn’t enough infill on my artificial turf?

A4: Insufficient infill can lead to the artificial turf blades flattening prematurely, reduced shock absorption (increasing injury risk), faster wear and tear on the turf blades, and a less stable playing surface.

Q5: Is there a limit to how much infill can be put on a field?

A5: Yes, overfilling can make the field too firm, affect ball roll, and create a surface that is difficult to groom properly. It’s crucial to adhere to the manufacturer’s recommendations for infill depth.

Q6: Are all football fields the same when it comes to infill?

A6: No, while standards exist, the specific infill quantities and types can vary based on the manufacturer, the specific artificial turf system used, the climate, and the desired playing characteristics. Some fields might use a layered system with sand at the bottom and rubber on top, while others might use a single infill type.

Q7: How does infill affect drainage on a soccer field turf?

A7: Properly installed infill, especially sand, helps facilitate drainage by creating channels for water to flow through the turf system and into the underlying drainage layers. If the infill becomes compacted, drainage can be compromised.

By comprehending the role of turf pellets and the factors influencing their quantity, sports facilities can ensure optimal performance, safety, and longevity from their artificial turf investments.